I recently replaced my current intruder alarm system with a Galaxy Dimension G3-520. These alarm systems are quite advanced, professional intruder alarm systems made by Honeywell and from hardware design and overall architecture are most definitely on the professional end of the scale. On the second-hand market (aka e-bay) they are not very expensive and are still relatively modern systems.

This is also a very “hackable” system making it friendly for DIY’ers and IoT systems and experiments and stuff. I do plan to write some other, possibly more interesting articles about this system and its overall hackability, but I thought I would start with a simple one, the mains transformer – which actually sucks! Here is why…

One of my first observations when running the panel on my desk was how hot the mains transformer was running. I measured it at around 55 degrees Celcius. Now with the lid on, and with the panel installed in an enclosed space, this is not ideal. It was getting hot enough that I thought there was something wrong with the transformer. I bought a second panel and transformer, and low and behold the transformer was just as bad.

The transformer is an Iron Core transformer, typical construction that most people are familiar with, and these types of transformers are known to have some inherent inefficiencies. The quality of the design and construction of the transformer play a big part in how efficiently the transformer performs.

There are two sources of loss in a transformer. The first is known as load loss and is as a direct result of resistance in the copper wire that makes up the transformer windings. Cheap copper alloys have higher resistance generally, as you draw current through the wire, heat is generated as a result of the resistance in that wire. The second source of loss is Core Loss, which is where the transformer consumes power it’s self, even when no load is present. The heat generation is caused primarily by resistance in the iron core of the transformer. The transformer in this panel suffers from both problems quite severely, its a poor quality transformer.

I did not want to install the panel with this heat-generating cheap-ass transformer, so I decided to fix it. I had two options, replace with a Switchmode or replace with a better quality passive transformer. Switchmode PSU’s are excellent for high power levels and small spaces, but they do suffer from power losses too. Moreover, there is the question of long-term reliability which I feel would be a problem for this application; there is nothing so simple and reliable as a transformer.

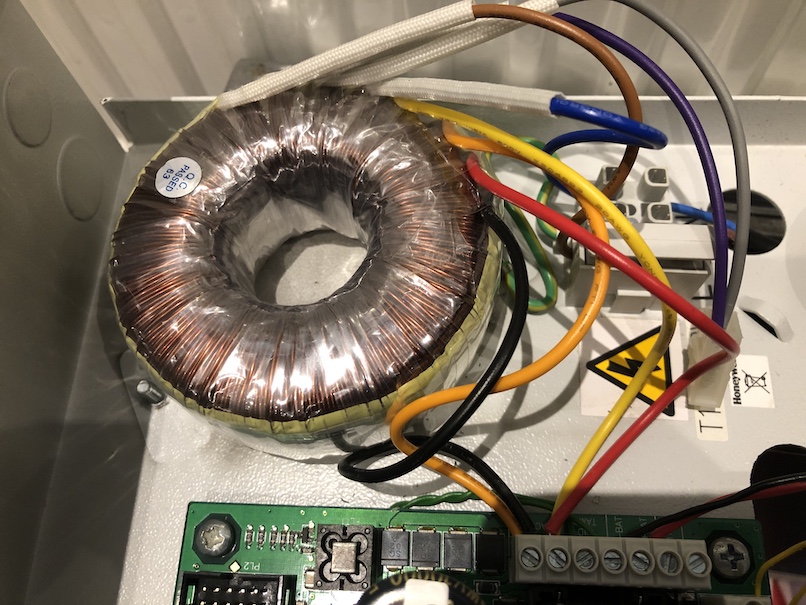

So to fix this in my panel, I have replaced the transformer with a toroidal type. Toroidal transformers are a better design and inherently have much lower core losses than a more traditional transformer. A good quality toroidal transformer should also not suffer load losses if they are correctly rated.

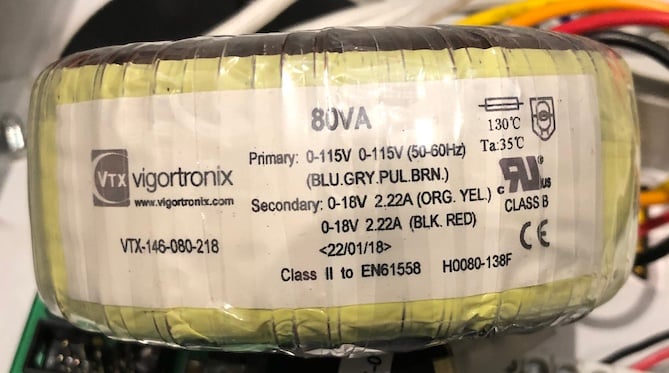

The panel is rated for 1.2A and 2.5A in its power and aux circuits, and needs to charge a Led Acid battery too, there are three 1A fuses and one 1.5A fuse on the board. So the power consumption of the panel and the accessories it can power from Aux 1 and Aux 2 totals about 44 watts (3.7A * 12V), and then you need at least another 18W to charge the standby battery so we are up to 63 watts of power. To give me about 20% headroom, I chose a transformer rated at 80W. Its an 80VA 18-0-18VAC secondary transformer made by a company called Vigortronix, part number VTX-146-080-218. You can get this from Farnell, or as I did, from an e-bay seller called Spiratronics, It cost me £23.50 shipped and included the mounting kit needed for a simple installation.

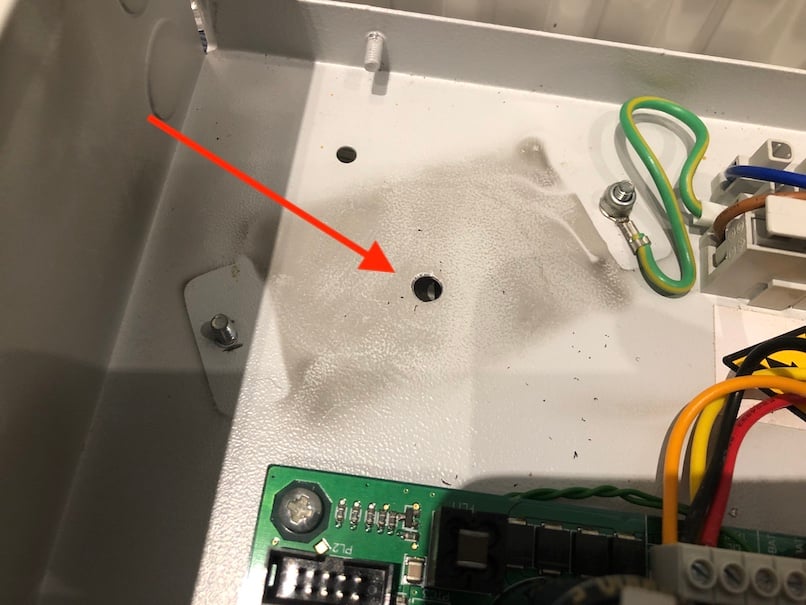

To fit the new transformer was as simple as drilling a hole in the right place, making sure the transformer does not hit the two studs that fixed the old transformer to the chassis and wiring the transformer. Wiring is dead simple, see the image below.

Primary side, you need the two windings in series for UK/EU and parallel for the US. For the UK, connect the grey and purple wires and insulate, connect the brown and blue to the (L)live and (N)neutral respectively. Secondary side, you need the two windings in parallel, so connect black and orange into one of the AC terminals on the PCB and connect the Red and Yellow wires and into the other AC terminal on the PCB.

The result. A transformer that does not get hot at all; it’s cold to touch after a week of running the panel and some attached peripherals. I have not measured it precisely (I may well do that at some point for the academic exercise), but basic measurements suggest there was around 3W of power loss in the old transformer with barely any load, that would be around £5/year in energy being wasted, not much but not trivial either. The significant benefit for me is that the panel is no longer generating the kind of heat that can build up in a closed space, its comforting to know that energy is not being wasted too and overall it just feels better, the transformer is no longer “just good enough.” its now correctly specified and just feels more professional.