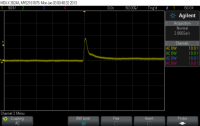

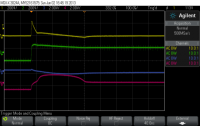

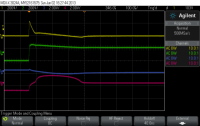

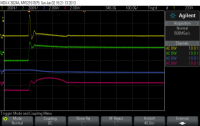

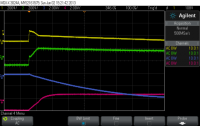

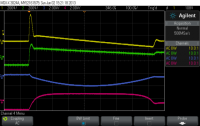

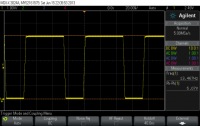

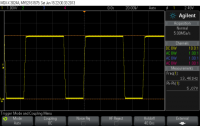

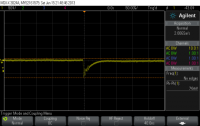

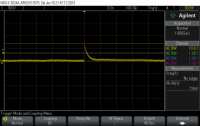

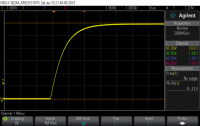

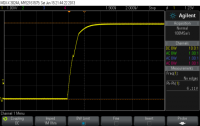

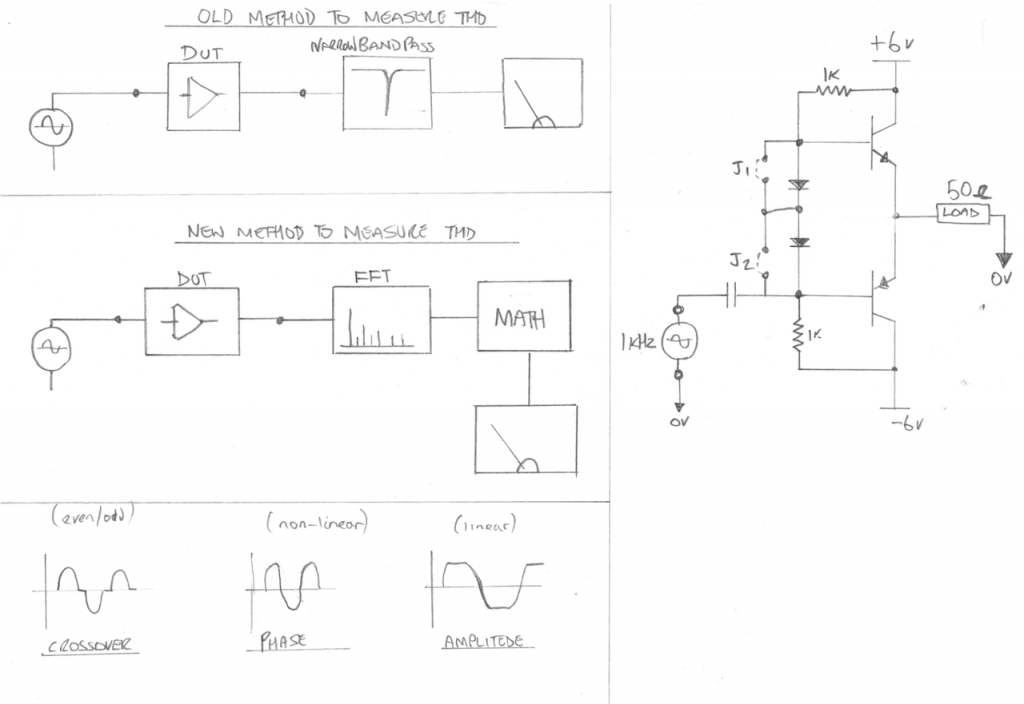

A piece of equipment I use rarely but when I do I find really useful is my HP 339A Distortion Measurement Set. Built in the 70’s this unit has a precision sine wave oscillator and distortion measurement section. One of the things thats really nice is the oscillator and the notch filter are tied together and the notch filter auto-nulls to make measurements really easy to accomplish.

The build quality of this unit is impeccable, made by HP when they were making stuff properly. The entire chassis is made from folded high quality aluminium sheets with capture nuts and really precise machining. The main oscillator switches are coupled using a bar and wafer scheme but both the oscillator and the filter are fully screened and isolated in their own chassis sub-sections. The smell from inside the unit is that old-school electronics smell I used to encounter all the time when I was a kid taking apart old TV’s and Record Players. I don’t know what chemicals exactly make that smell but I am pretty sure if you could bottle it you could sell it – there is an idea for a unique aftershave! It could be called “Ye’old TV Man”!

Anyway, hope you will find the video interesting. Thanks for watching.

You must

You must